Application of infrared temperature sensors in the power industry

2025-07-22

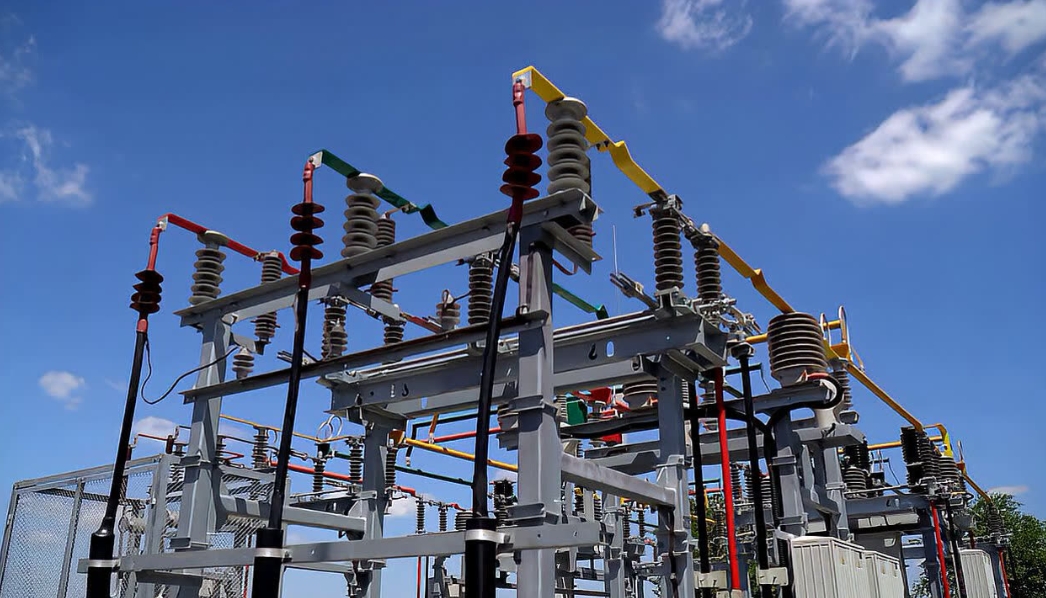

During the operation of the power transmission and transformation system, the surface temperature of the equipment rises due to the thermal effect of the current, and this process is accompanied by the release of infrared radiation. Through high-precision infrared temperature sensors, these radiation signals can be captured in real time and converted into temperature data, so as to achieve rapid and accurate judgment of the operating status of the power transmission and transformation equipment. The non-contact temperature measurement method has become an indispensable technical means in the operation and maintenance management of power equipment.

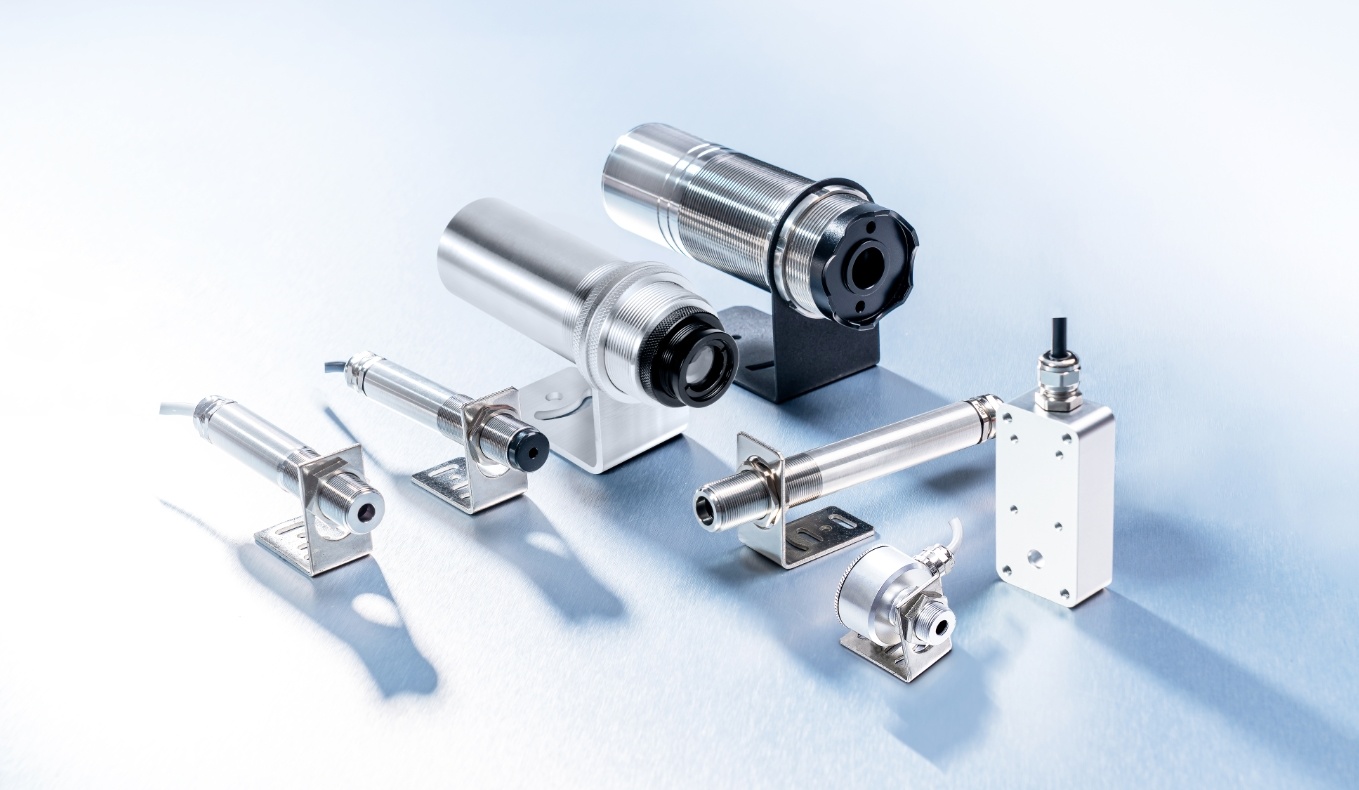

IR temperature sensors have the advantages of rapid response, high accuracy, and no need to contact the measured object. They are especially suitable for real-time online monitoring of the status of high-voltage dangerous equipment. It can effectively identify local overheating caused by poor contact, loose bolts, abnormal wiring, uneven current density and other factors. Even if there is a slight abnormal heating inside the transformer, the sensor can sense the slight change of the thermal field of the shell, so as to timely warn of potential risks.

In the daily inspection of the substation, the traditional manual inspection method is difficult to detect subtle heating hazards in time. The introduction of infrared temperature sensors not only improves the inspection efficiency, but also greatly enhances the visualization and traceability of abnormal conditions. Through systematic deployment, key parts such as disconnectors, wiring terminals, wire connection points, busbar bridges, etc. can be intelligently monitored around the clock.

During the operation of the transformer, problems such as loose wiring clamps, oxidation of pads, and aging of vibration reduction components often lead to abnormal heating. If not handled in time, it is very easy to cause line failures or equipment damage. Infrared temperature sensors can quickly detect these hot spots, avoiding the safety risks brought about by the operation of equipment under hidden dangers. At the same time, the sensor also supports data storage and remote transmission functions, which can provide continuous data support for the health management of power equipment throughout its life cycle.

With the continuous integration of smart grids and modern information technology, the application of infrared temperature sensors in power transmission and transformation equipment is becoming more and more extensive, not only limited to detection functions, but also extending to intelligent operation and maintenance, automatic early warning, remote diagnosis and other directions. Its non-contact, visual, and automated monitoring characteristics make it an important part of the current digital upgrade of power equipment operation and maintenance.

In the future, with the continuous development of infrared sensing technology, its sensitivity, resolution and environmental adaptability will be further improved. Infrared temperature sensors will show higher application value in power inspection, status assessment, accident prevention and other aspects, providing stronger technical support for ensuring the stable and safe operation of the power system.

RECOMMEND NEWS

Contact Us

· Our company was founded in 1965 and has more than 60 years of experience in sensor R & D and production.

· Our products have obtained CE, RoHS, ISO, ATEX and other international certifications.

Please leave your contact information to get one-on-one product selection guidance and quotation services from professional engineers.