News Center

Application of pressure transmitter in secondary water supply industry

- Categories:Industry information

- Time of issue:2019-05-10 10:43

(Summary description) At present, in order to prevent the impact on urban residents' water use, our country does not allow domestic and production water pumps to be directly installed on the municipal pipeline network. In order to solve the problem that the water supply equipment can be connected in series to the municipal water supply pipe network without generating negative pressure, and it does not affect other users' water use, it is necessary to add a flow controller, a sub-cavity stabilized pressure compensation tank, etc. between the water pump inlet and the municipal pipe network. The flow controller constantly monitors the pressure of the municipal pipe network. While ensuring that the municipal pipe network does not produce negative pressure, it can also make full use of the original pressure of the municipal pipe network. At this time, it is necessary to use a non-negative pressure water supply system. When municipal piped tap water enters the regulating tank at a certain pressure, the air in the stabilized pressure compensation tank is discharged from the vacuum eliminator, and the vacuum eliminator is automatically closed after the water is full. When the tap water can meet the water pressure and water volume requirements, the water supply equipment directly supplies water to the water pipe network through the bypass check valve; when the pressure of the tap water pipe network cannot meet the water requirements, the system will pass pressure sensors, or pressure controllers, and electricity. The contact pressure gauge gives the pump signal to start the pump operation. The variable frequency constant pressure water supply system is mainly composed of PLC control unit, frequency converter, pump motor, water supply pipe network, water storage tank and pressure sensor, as shown in the figure below. The constant pressure water supply pump station uses multiple pumps and motors, which can be put into operation according to the water consumption. Therefore, the power of a single pump motor is not large, and the system has a backup pump for maintenance without stopping work. The running number of the water pump is controlled by PLC, and the motor speed is controlled by the frequency converter to meet the needs of different water consumption. The pressure sensor is one of the main accessories in non-negative pressure water supply equipment and variable frequency constant pressure water supply equipment. The original remote pressure gauge is upgraded to a pressure sensor. The previous remote pressure gauge not only makes the entire water supply system unstable, but also It also needs to be replaced frequently, which increases the cost of after-sales service. The use of pressure sensors can not only solve the problem of unstable water supply, but also is not easy to damage. At the same time, it also reduces after-sales costs. Through the high-sensitivity pressure switch or pressure sensor installed on the water supply pipe network, the pressure change of the water supply pipe network when the water consumption changes is detected, and the changing signal is continuously transmitted to the microcomputer. According to different operating conditions, the compensation amount is dynamically controlled to achieve dynamic pressure balance and ensure a constant pressure in the water supply pipe network to meet the water needs of users. In fact, the pressure sensor can be divided into: pressure sensor and pressure transmitter according to the output signal and whether the amplifier circuit is installed in the body. At the same time, according to whether it can measure corrosive media and adapt to harsh environments, it can be divided into: general-purpose and isolated. According to the different signals, it can be divided into current-type pressure sensors: generally 4-20mA; and voltage signal-type pressure sensors. : 0 to 12V. Hunan Firstrate Sensor Co., Ltd. is a professional sensor manufacturer in the secondary water supply industry. Products are sold at home and abroad, and have reached long-term and stable cooperative relations with many water supply equipment suppliers. Our products cover various applications such as non-negative pressure water supply equipment, variable frequency water supply equipment, constant pressure water supply equipment, secondary water supply equipment, single pump variable frequency water supply equipment, integrated smart pumping station, and urban water supply pipe network pressurized pumping station, etc. The secondary water supply industry manufacturers have applicable requirements for professional sensors that are waterproof, dustproof, and resistant to frequency conversion interference. Our products have leading technology, exquisite structure, reliable quality, and strong environmental adaptability. Welcome to inquire and cooperate!

Application of pressure transmitter in secondary water supply industry

(Summary description) At present, in order to prevent the impact on urban residents' water use, our country does not allow domestic and production water pumps to be directly installed on the municipal pipeline network. In order to solve the problem that the water supply equipment can be connected in series to the municipal water supply pipe network without generating negative pressure, and it does not affect other users' water use, it is necessary to add a flow controller, a sub-cavity stabilized pressure compensation tank, etc. between the water pump inlet and the municipal pipe network. The flow controller constantly monitors the pressure of the municipal pipe network. While ensuring that the municipal pipe network does not produce negative pressure, it can also make full use of the original pressure of the municipal pipe network. At this time, it is necessary to use a non-negative pressure water supply system.

When municipal piped tap water enters the regulating tank at a certain pressure, the air in the stabilized pressure compensation tank is discharged from the vacuum eliminator, and the vacuum eliminator is automatically closed after the water is full. When the tap water can meet the water pressure and water volume requirements, the water supply equipment directly supplies water to the water pipe network through the bypass check valve; when the pressure of the tap water pipe network cannot meet the water requirements, the system will pass pressure sensors, or pressure controllers, and electricity. The contact pressure gauge gives the pump signal to start the pump operation.

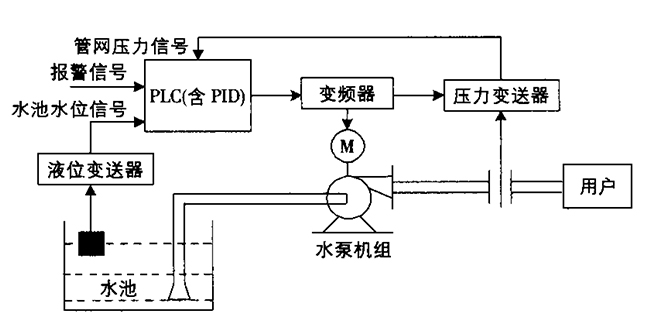

The variable frequency constant pressure water supply system is mainly composed of PLC control unit, frequency converter, pump motor, water supply pipe network, water storage tank and pressure sensor, as shown in the figure below.

The constant pressure water supply pump station uses multiple pumps and motors, which can be put into operation according to the water consumption. Therefore, the power of a single pump motor is not large, and the system has a backup pump for maintenance without stopping work. The running number of the water pump is controlled by PLC, and the motor speed is controlled by the frequency converter to meet the needs of different water consumption.

The pressure sensor is one of the main accessories in non-negative pressure water supply equipment and variable frequency constant pressure water supply equipment. The original remote pressure gauge is upgraded to a pressure sensor. The previous remote pressure gauge not only makes the entire water supply system unstable, but also It also needs to be replaced frequently, which increases the cost of after-sales service. The use of pressure sensors can not only solve the problem of unstable water supply, but also is not easy to damage. At the same time, it also reduces after-sales costs.

Through the high-sensitivity pressure switch or pressure sensor installed on the water supply pipe network, the pressure change of the water supply pipe network when the water consumption changes is detected, and the changing signal is continuously transmitted to the microcomputer. According to different operating conditions, the compensation amount is dynamically controlled to achieve dynamic pressure balance and ensure a constant pressure in the water supply pipe network to meet the water needs of users.

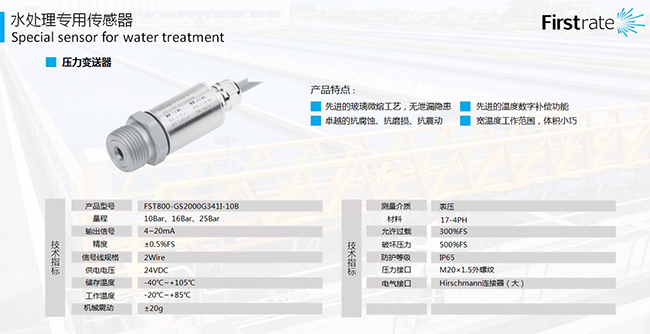

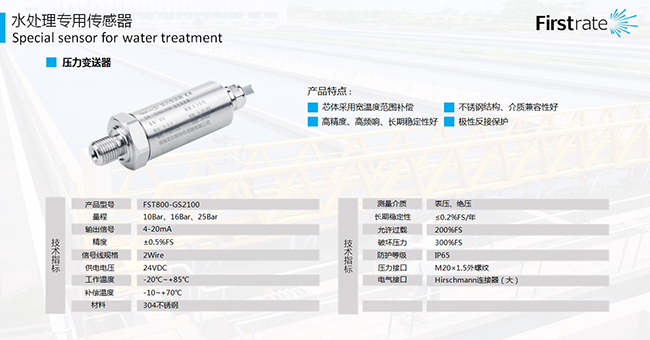

In fact, the pressure sensor can be divided into: pressure sensor and pressure transmitter according to the output signal and whether the amplifier circuit is installed in the body. At the same time, according to whether it can measure corrosive media and adapt to harsh environments, it can be divided into: general-purpose and isolated. According to the different signals, it can be divided into current-type pressure sensors: generally 4-20mA; and voltage signal-type pressure sensors. : 0 to 12V.

Hunan Firstrate Sensor Co., Ltd. is a professional sensor manufacturer in the secondary water supply industry. Products are sold at home and abroad, and have reached long-term and stable cooperative relations with many water supply equipment suppliers. Our products cover various applications such as non-negative pressure water supply equipment, variable frequency water supply equipment, constant pressure water supply equipment, secondary water supply equipment, single pump variable frequency water supply equipment, integrated smart pumping station, and urban water supply pipe network pressurized pumping station, etc. The secondary water supply industry manufacturers have applicable requirements for professional sensors that are waterproof, dustproof, and resistant to frequency conversion interference. Our products have leading technology, exquisite structure, reliable quality, and strong environmental adaptability. Welcome to inquire and cooperate!

- Categories:Industry information

- Time of issue:2019-05-10 10:43

Top Ranking

RECOMMEND NEWS

Top Ranking

RECOMMEND NEWS

ONLINE MESSAGE

WRITE A MESSAGE TO US

v

Contact us

Tel:

+86 731-86171990

Email:

sales@firstratesensor.com

Address: 4th Floor, Building 1, Zhitingyuan, Zhenhua Road, Yuhua District, Changsha City, Hunan Province,China.