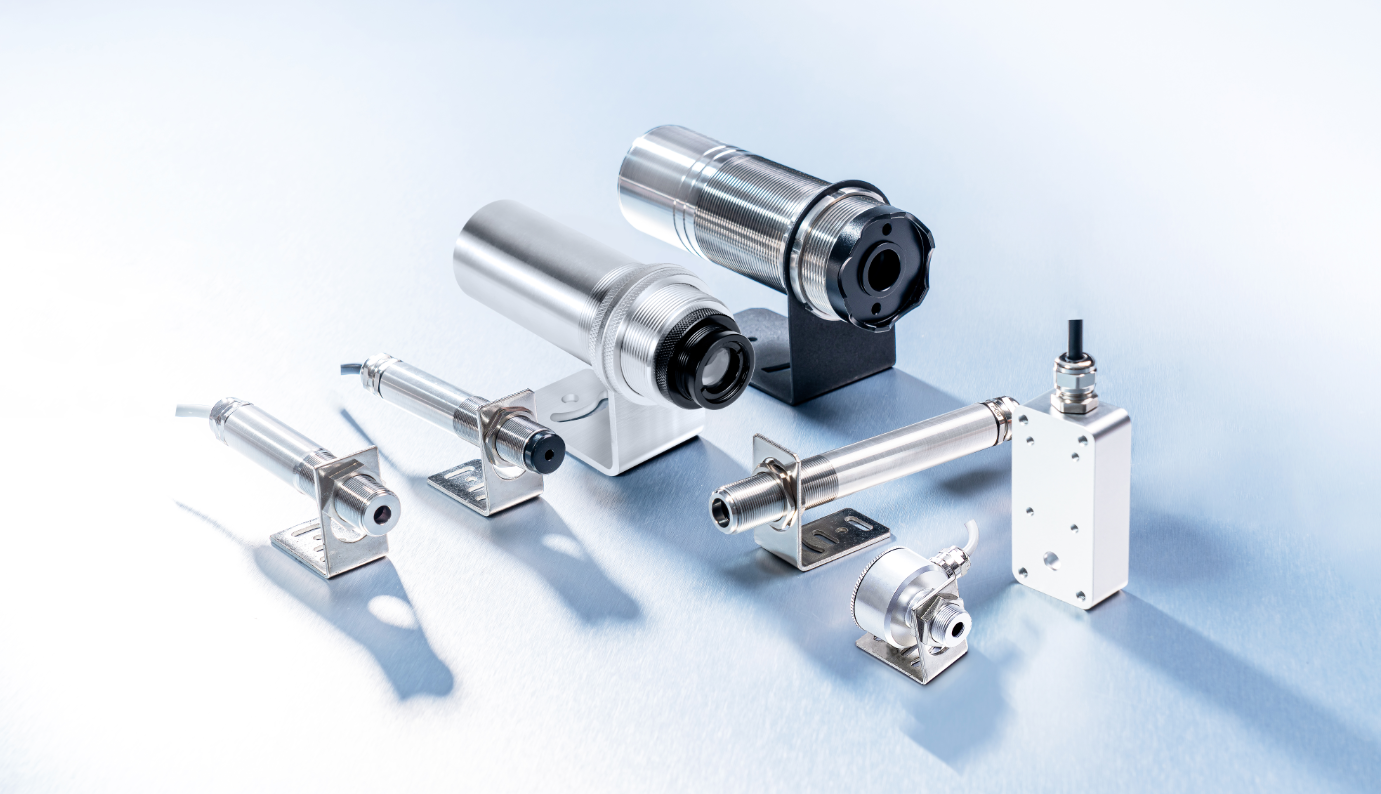

How to safeguard food quality Compact Infrared Temperature Sensors

2025-05-20

Non-contact measurement ensures food safety

Traditional contact temperature measurement methods pose a risk of contamination, especially during food processing. Compact infrared temperature sensors utilize non-contact infrared technology to accurately measure temperature in real time without touching the surface of the object being measured. This not only eliminates the risk of contamination between the food product and the measuring device, but also ensures accurate and reliable measurements.

These sensors are widely used in all stages of food production. They quickly and accurately monitor temperature changes inside and outside the equipment, ensuring that the process temperature remains within specified limits. This stability helps maintain consistent product quality and prevents problems such as overheating or uneven heating.

Pre-Packaging Temperature Measurement

Measuring the temperature of food prior to packaging is especially important for perishable items such as meat and dairy products. Sensors can quickly detect the surface temperature of food products to ensure that they are within a safe temperature threshold before entering the packaging process.

Cold chain transportation and storage

During cold chain logistics and storage, any temperature fluctuations can affect food quality. These sensors provide real-time monitoring of environments such as cold storage facilities or refrigerated trucks, quickly detecting anomalies and ensuring food safety throughout the supply chain.

Compact infrared temperature sensor with millisecond response time and ±1% measurement accuracy ensures accurate, fast data feedback. The sensors are designed to be resistant to interference and maintain stable performance even in complex electromagnetic environments, making them highly adaptable to the challenges of food processing lines.

These sensors are housed in rugged anodized aluminum housings that are dirt- and corrosion-resistant, allowing them to operate reliably in the high-temperature, humid conditions common in food processing plants. Their non-contact measurement design also extends service life and reduces maintenance costs.

Compact infrared temperature sensors are widely used in the food industry, not only to improve production efficiency, but also to help companies maintain food quality and safety. From the production floor to storage and transportation, accurate temperature monitoring plays a key role in ensuring product integrity and supporting more efficient and smarter production management.

RECOMMEND NEWS

Contact Us

· Our company was founded in 1965 and has more than 60 years of experience in sensor R & D and production.

· Our products have obtained CE, RoHS, ISO, ATEX and other international certifications.

Please leave your contact information to get one-on-one product selection guidance and quotation services from professional engineers.