News Center

Sensor + cloud monitoring makes uninterrupted production possible

- Categories:Industry information

- Time of issue:2017-08-31 17:38

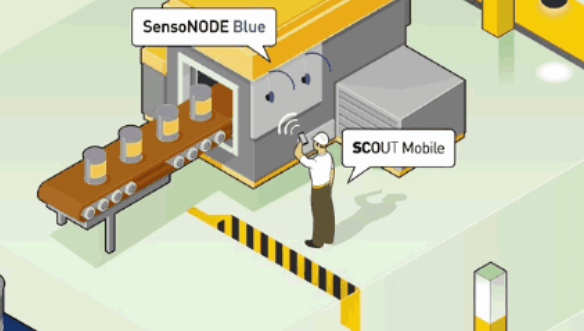

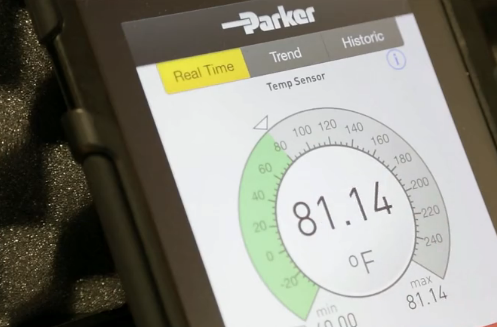

(Summary description) Foreign R&D institutions have launched cloud monitoring software and SensoNODE sensors to allow users to access machine status data through a Web browser, so as to achieve the purpose of identifying operations and improving performance. Industry 4.0 and the Internet of Things are bringing huge benefits to industry, and innovative solutions bridge the gap between modern technology and traditional manufacturing. The R&D technology is a cloud-based continuous monitoring solution that reverses the chaos of traditional asset monitoring, enabling users to centrally access asset information, whether on site or miles away. The remote continuous monitoring system allows factory employees to access asset data from any place connected to the Internet, monitor and solve machine health problems, analyze production or manufacturing potentially dangerous situations, and receive alarm notifications of problems via email, text, and system messages. In addition, it also supports exporting data for analysis and reporting, and multiple users can monitor the data at the same time. The researcher David Shannon said that continuous monitoring means that the system always pays attention to problems and reminds users when there are problems. He said this allows employees to "manage by exception" and focus on those assets and/or processes that require their attention, instead of spending unnecessary man-hours to manually check and collect data on assets/processes that are correctly operated. Check out the Reconnaissance Cloud Software product page for more details. David Shannon said that continuous monitoring means that the system will constantly monitor equipment and alert users when there are problems, so that employees can manage exceptionally and focus on those assets or processes that need their attention without spending unnecessary human time. To manually check and collect asset or process data for correct operation.

Sensor + cloud monitoring makes uninterrupted production possible

(Summary description) Foreign R&D institutions have launched cloud monitoring software and SensoNODE sensors to allow users to access machine status data through a Web browser, so as to achieve the purpose of identifying operations and improving performance. Industry 4.0 and the Internet of Things are bringing huge benefits to industry, and innovative solutions bridge the gap between modern technology and traditional manufacturing.

The R&D technology is a cloud-based continuous monitoring solution that reverses the chaos of traditional asset monitoring, enabling users to centrally access asset information, whether on site or miles away.

The remote continuous monitoring system allows factory employees to access asset data from any place connected to the Internet, monitor and solve machine health problems, analyze production or manufacturing potentially dangerous situations, and receive alarm notifications of problems via email, text, and system messages. In addition, it also supports exporting data for analysis and reporting, and multiple users can monitor the data at the same time.

The researcher David Shannon said that continuous monitoring means that the system always pays attention to problems and reminds users when there are problems. He said this allows employees to "manage by exception" and focus on those assets and/or processes that require their attention, instead of spending unnecessary man-hours to manually check and collect data on assets/processes that are correctly operated. Check out the Reconnaissance Cloud Software product page for more details.

David Shannon said that continuous monitoring means that the system will constantly monitor equipment and alert users when there are problems, so that employees can manage exceptionally and focus on those assets or processes that need their attention without spending unnecessary human time. To manually check and collect asset or process data for correct operation.

- Categories:Industry information

- Time of issue:2017-08-31 17:38

Top Ranking

RECOMMEND NEWS

Top Ranking

RECOMMEND NEWS

ONLINE MESSAGE

WRITE A MESSAGE TO US

v

Contact us

Tel:

+86 731-86171990

Email:

sales@firstratesensor.com

Address: 4th Floor, Building 1, Zhitingyuan, Zhenhua Road, Yuhua District, Changsha City, Hunan Province,China.